Background

As of October 2018 I have about 6 months of 3D scanning under my belt. I feel that is enough confidence to start advertising my services. A huge portion of my business is manufacturing parts to fit other parts. Usually things aviation related like a wingtip to fit a particular wing or an instrument panel to fit inside a cockpit. It has been a rather steep learning curve but I am now producing scans that are extremely accurate for the work I do so I have decided to market my services.

The primary goal of my scanning ability was to be able to scan larger than normal parts. Most of what I do is big when compared to average 3D scanning. A lot of companies can scan things that fit on your desk. When I searched for this service locally here in Kansas City I was unable to find anyone with the capability to scan objects as large as my projects are. For that reason I took it upon myself to fill the void.

Solution

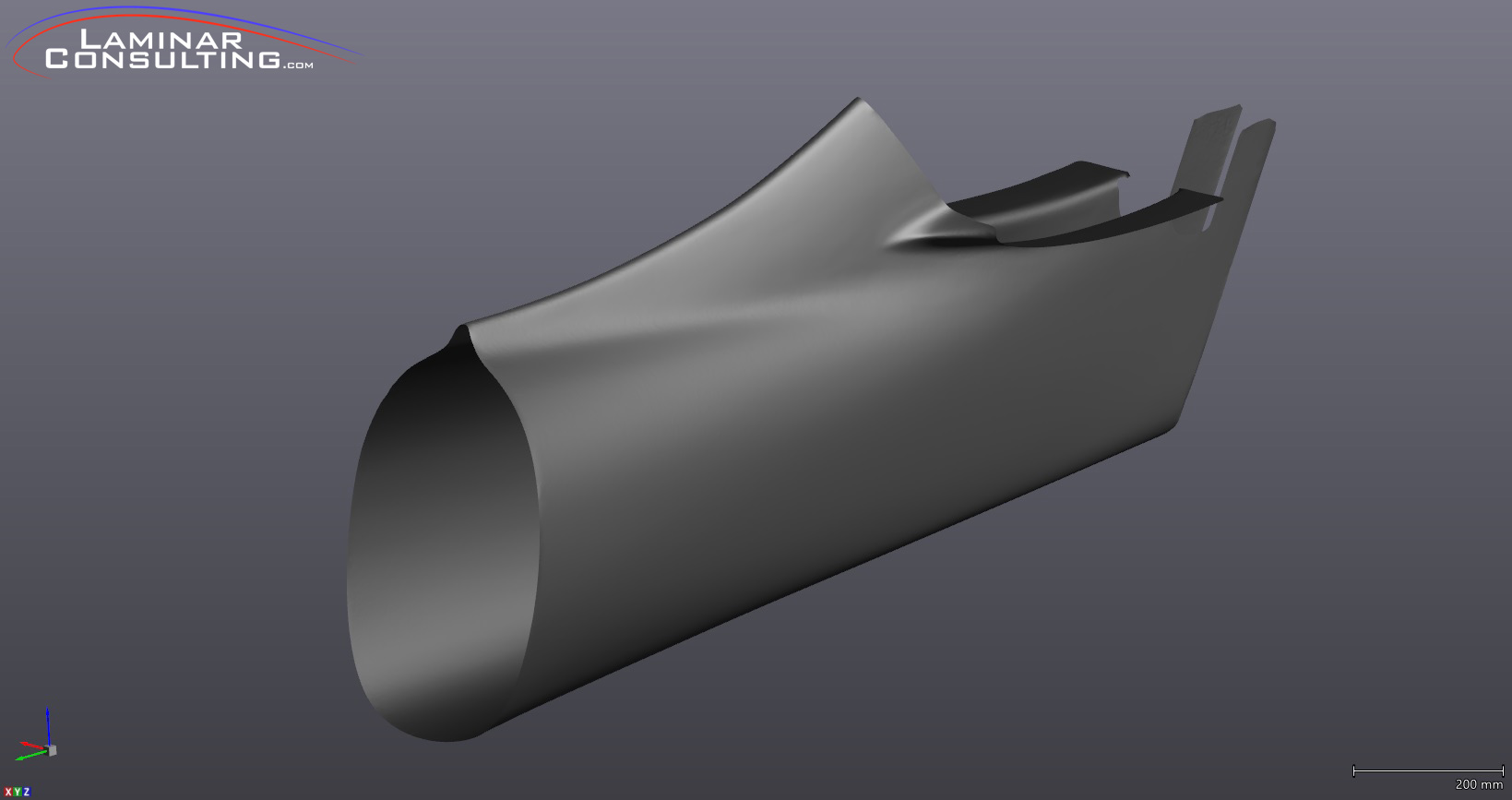

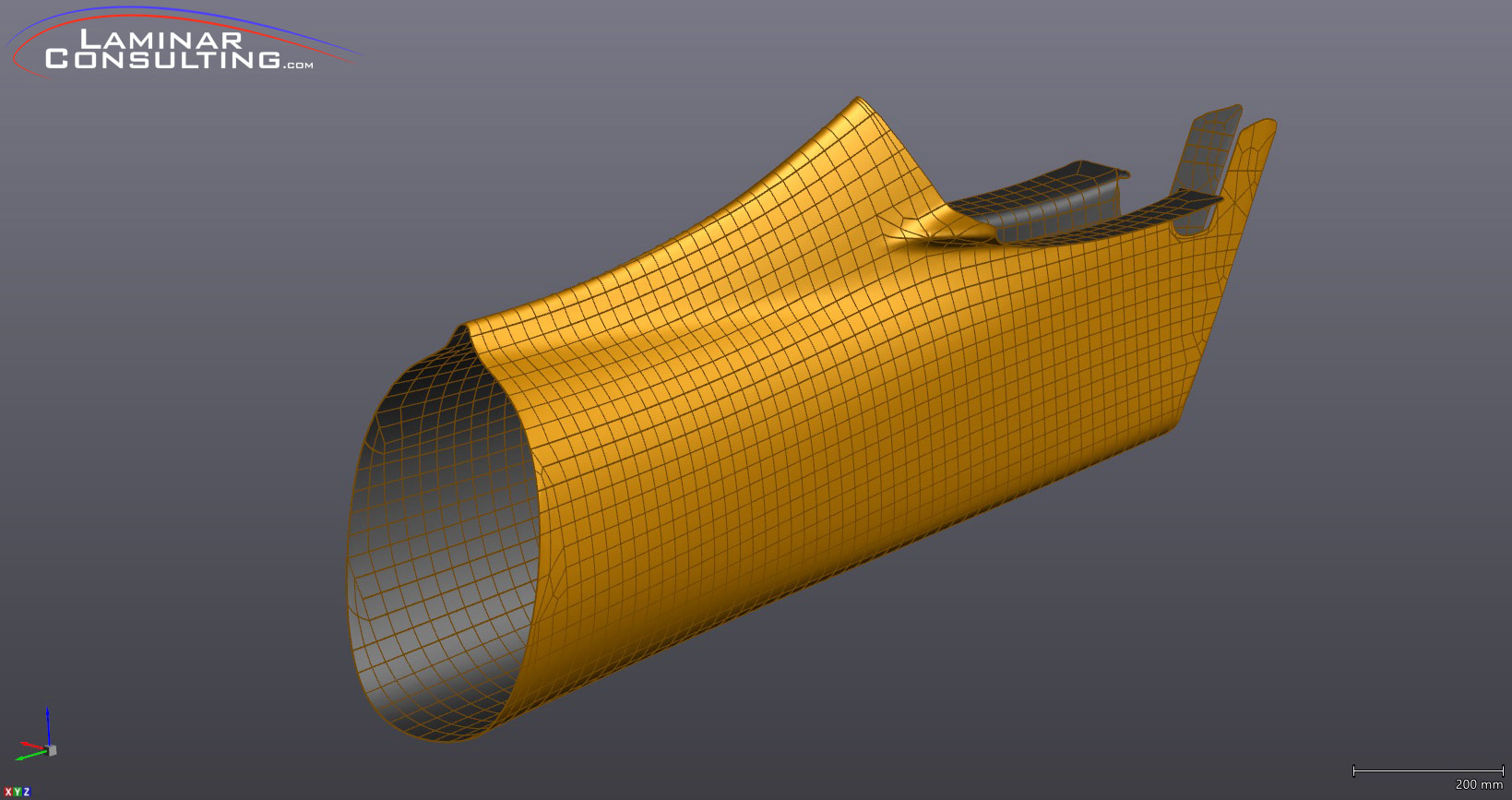

Some of the goals I had for this phase of my business included capturing geometry that would often times be hard to scan. Something as simple as pencil marks on a mold would not show up on most scanners available on the market. When I discovered the option to include color, or basically overlay images as a texture, that solved a lot of issues for me. This photo was the first thing I scanned when I took the scanner out of the box. Pretty amazing.

Some of the goals I had for this phase of my business included capturing geometry that would often times be hard to scan. Something as simple as pencil marks on a mold would not show up on most scanners available on the market. When I discovered the option to include color, or basically overlay images as a texture, that solved a lot of issues for me. This photo was the first thing I scanned when I took the scanner out of the box. Pretty amazing.

Another key requirement was the ability to be extremely mobile. Obviously most of the time I have to travel to the airplane/thing I’m working on, rather than it come to me. Therefore having a scanner that easily travel with very low requirements was essential. Basically all I need is power, my laptop and the scanner. I even have a small portable 1000w generator that can travel with me to in extremely remote conditions, when needed.

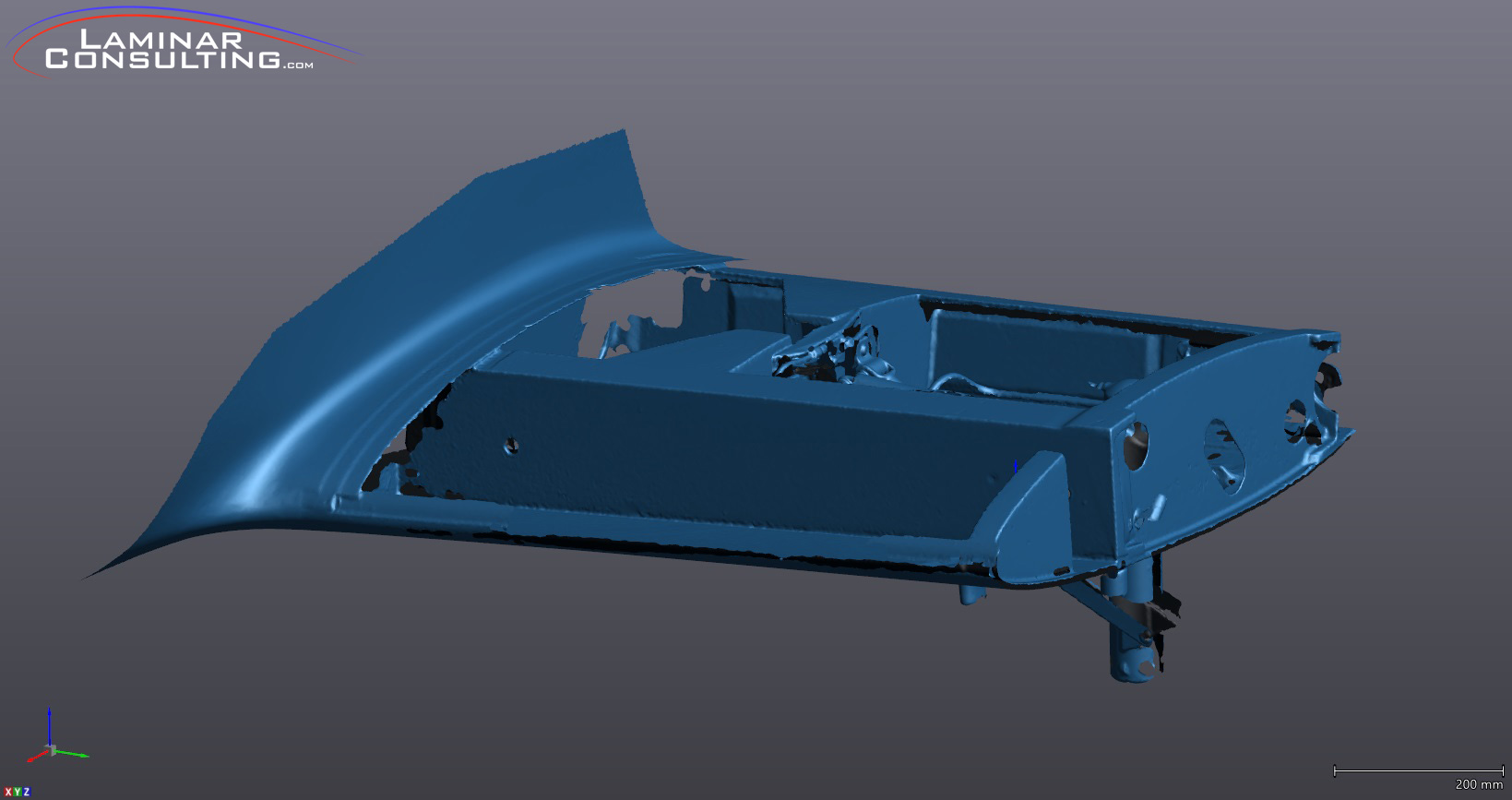

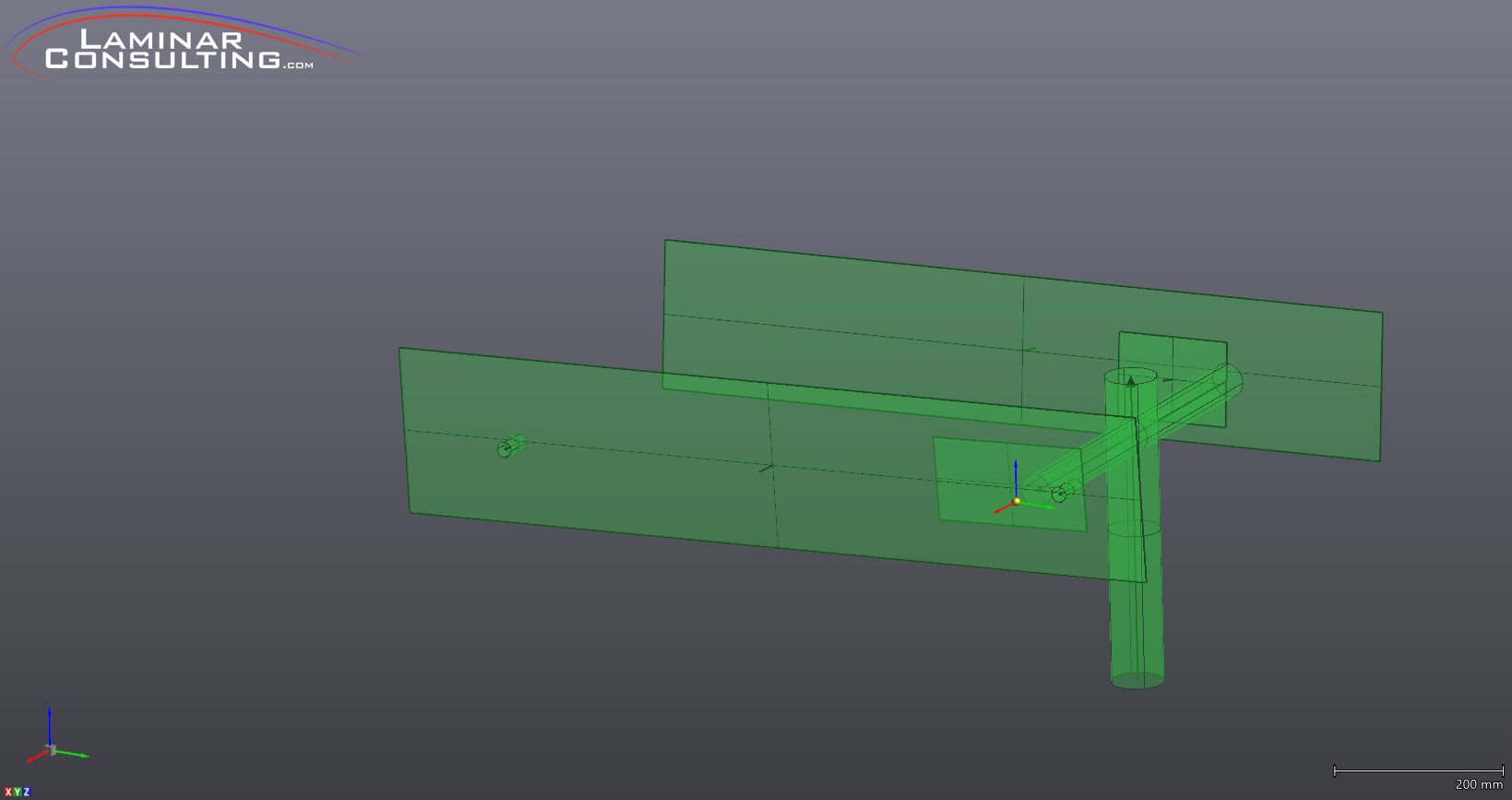

What I quickly discovered speaking with other commercial scanning services was that all they provided was the raw scan mesh itself. That doesn’t make it totally worthless, but it seriously cuts down on the scans value as most of the CAD platforms have less than ideal tools to identify entities from the mesh. For example, labeling a tube as a cylinder with a known dimension, or creating a surface that can be edited from the mesh. These would all be requirements for me so I’m sure they are very useful things customers would request as well.